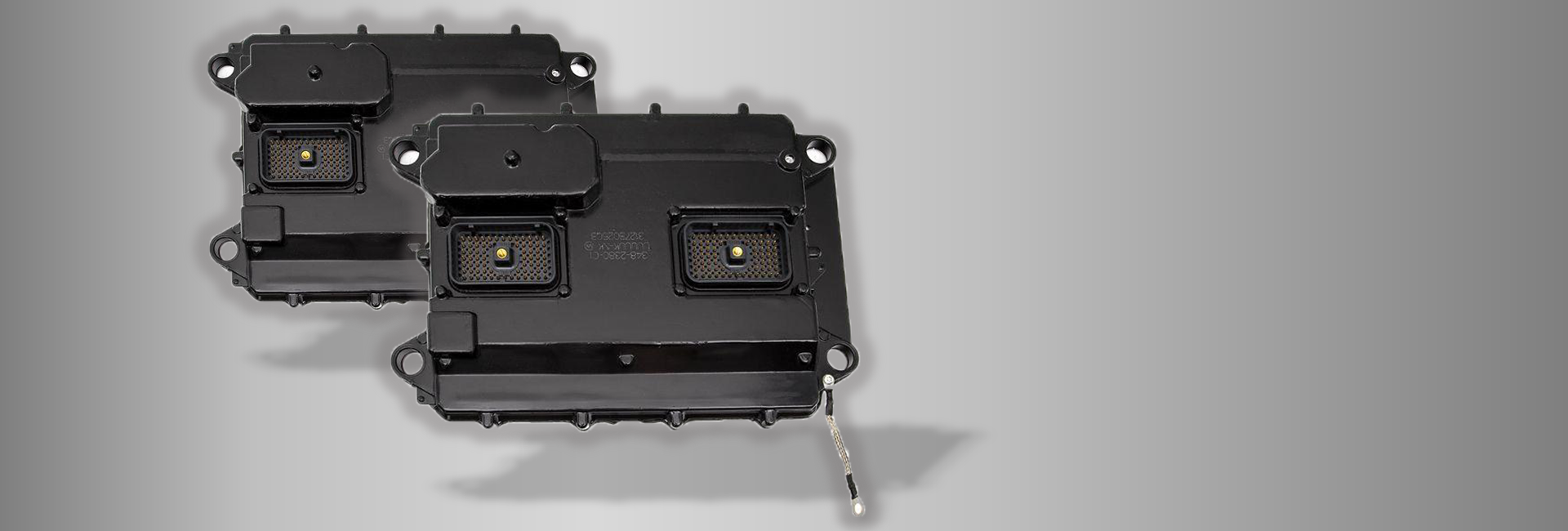

Generator control system service and programming

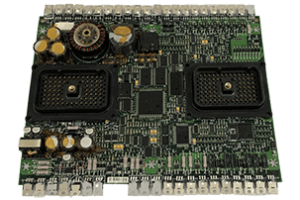

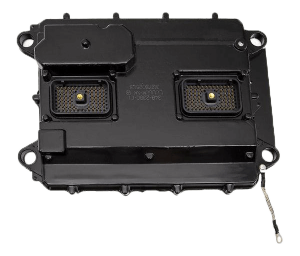

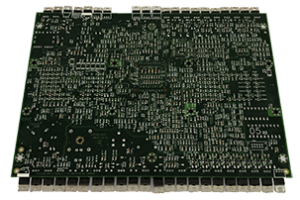

One of the most important and precise parts of any generator is its main processor (ECM), which handles all engine parameters from the sensors and Module power supply and all of the engine processing work. In the event of the slightest malfunction in information or processing, faults and codes occur and the engine crashes, so it should be noted that careful consideration is given to the operation of the Generator Control System (ECM) system,Don't get into trouble.Depending on the type of engine, the number of ECMs is reduced or increased, for example, in the 3520 engine, three types of ECMs can be used to communicate with each other through the CatLink network and to exchange information between them.

For example:

-

ECM Slave

-

ECM Master

-

(ASM) Auxiliary Sensor Module

Failure factors in ECM

Water Heater Generator

Improper insulation of the heater also causes insulation to cause a connection between the generator and the heater body, causing damage to the generator control system (ECM).

Battery to Battery

Sometimes due to poor battery life or discharging the battery, batteries can be generated in the generators which can damage the ECMs.

Ground Wire

The lack of ground wire or inadequate ground wire causes short circuit control and excess voltage, which can damage electrical components and the ECM.

Remove The Battery From The Generator

Removing the battery from the generator when turned on will damage all parts of the control system (ECM).

Sensor Failure

Due to the interconnection of the sensors, high current is drawn from the power outputs of the sensors, which causes the control system to fail.

Improper Battery Life

Battery failure and failure can lead to high voltage from the battery when switched on, causing electrical components to oscillate.

Abilities Of The Ayriko Company

With this experience, Ayriko company can handle all winflash adjustments as well as repairs and implement key engine settings by examining the generator control system .

-

Planning for FLASH and EEPROM ICs

-

Defective board troubleshooting

-

Replacement of defective parts

-

Providing all parts